Impact wrench is a pneumatic power tool with immense torque but little exertion to match. It’s primarily used by mechanics and machine operators who are looking to save time, energy, and money while working on machinery. An impact wrench offers a rotating power-delivery mechanism that delivers powerful torque to the user — it can be used for tightening bolts or loosening rusted ones.

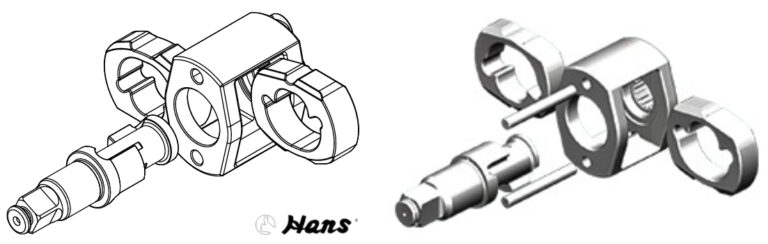

Dynamic Analysis of the Hammer Mechanism “Twin Hammer” of Impact Wrench details the function of a hammer mechanism known as “Twin Hammer.” The Twin Hammer, found in impact wrenches, operates with two identical blocks that strike one another. This hammer mechanism is connected to the input shaft of the device by means of an involute spline which allows for better transmission of high torque from the motor.

💡 Understanding Composite Materials in HansTools Impact Wrenches

At HansTools, we use composite materials—a combination of two or more substances—to improve both performance and functionality. These materials are carefully selected for their ability to deliver high strength, light weight, and specialized performance in demanding environments.

🌍 Why Use Composites?

Composite materials are widely used in aerospace, where components like wing panels and fuselage sections must be light yet strong. We apply the same thinking to our tools—delivering strength without unnecessary weight, and durability without sacrificing control.

🔧 Lightweight Impact Wrench Models:

• 86117, 88117, 88116

• Material Composition: Aluminum + Plastic + Rubber Handle

• Key Advantage: Optimized for users who need a lightweight tool without compromising on strength or torque output.

🖐️ Designed for One-Handed Operation:

• 84118–83119, 84119, 86119, 88119

• Material Composition: Aluminum + POM (Polyoxymethylene) + Rubber

• Key Advantage: Balanced for single-handed use, ideal for mechanics who require precision, agility, and control in tight spaces.

🧪 What Makes Composites Ideal for Impact Wrenches?

• Strength-to-weight ratio: Delivers power with reduced fatigue

• Enhanced grip and control: Rubber handles and ergonomic designs

• Durability: Resistant to corrosion, temperature changes, and heavy use

• Versatility: Suitable for both workshop and field applications

While composite materials can be more expensive, they are often the best solution when performance, comfort, and longevity are critical.

POM – also known as acetal or polyacetal. It is 100% recyclable. POM is known as polyformaldehyde, polymethylene glycol and polyoxymethylene glycol.

POM resins are regarded to applied in the production of precision parts for good stability and high capability.

- Automotive

- Electrical & electronic

- Industrial

- Drug Delivery

🛠️ How to Lubricate Pneumatic Tools Properly

🛠️ How to Lubricate Pneumatic Tools Properly

Pneumatic tools must be lubricated regularly to run smoothly and last longer. Use air tool oil to dissolve gum, sludge, and calcium buildup, while also protecting against moisture.

🔹 Before Use: Apply a few drops of oil to ensure smooth operation.

🔹 After Use: Add oil again to keep the tool lubricated during storage.

🔹 Inline Oilers: These help maintain consistent lubrication during use.

🔹 Note: Some tools may require special lubricants—always check the manual.

Look for the “Oil Daily” marking on your tool and follow it—a small step that prevents big problems.