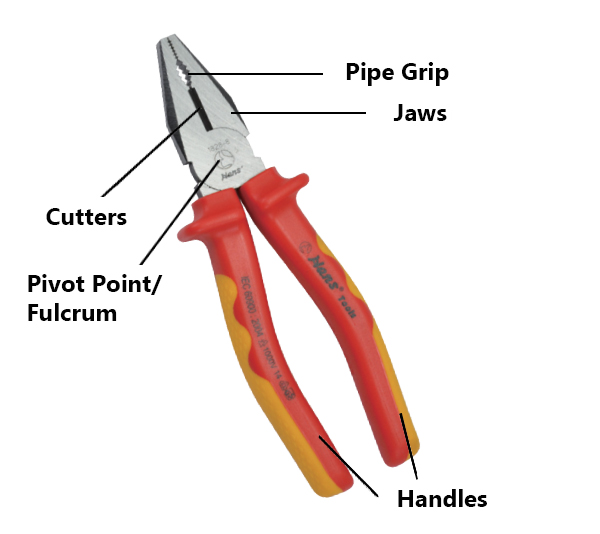

Pliers are a tool that has a lot of parts and all of them have a function. All of the parts do something different for the plier to work. Tip – This is at the end of the pliers and it is used for anything round. Pipe Grip – These are for gripping pipes. Cutters – This part is for cutting wires and cables. Jaws – The working end of the pliers is what does the gripping. The pivot point or fulcrum is where the handles meet and can open up again. This is how the jaws move up and down. Handles – You can have curved or straight handles on your pliers.

This multi-tool is shaped like a hammer, with a fulcrum instead of a flat head. This allows you to cut wires of varying gauges. The left side has a hammer surface for pounding in staples, and the rounded grip hole fits well in your hand.

You can use the right claw to remove staples, and both sides have gripping surfaces.

- Flat nose pliers

are designed to hold flat, large objects together. This makes them useful for holding and manipulating larger pieces of metal as well as bending wire into 90-degree angles. Flat nose pliers are ideal for large, flat surfaces. They’re great for holding objects together and bending wire at 90-degree angles without kinking or buckling it.

- Insulated hand tools

are designed to protect you against injury in the event that you make contact with an energized source. Insulated tools need to be rated up to 1,000 volts to ensure your safety during live wire contact. The mark indicates that it has been tested and rated by an accredited agency for its ability to resist high voltage in the event of a shock.

are a type of plier with an electrical or mechanical cutting and gripping function. These pliers have an angled opening on the jaw which creates an electrician’s reamer; these are used for cutting wire and bending it as necessary. The angular edges at the end of the jaws are designed to ream down ridges and burs in cut pipes and to grip wire.

These needle-nose pliers are made of heat-treated steel, making them as sturdy as they are beautiful. The pliers have a longer reach than standard pliers and make it easy to get into tight spaces where other tools can’t fit.

are specially designed to remove oil filters on engines of all shapes and sizes. The durable rubber grips provide excellent leverage for stubborn filters, and the plier teeth bite into metal engine oil filters to hold the filter in place while removing it with ease.

are used for making round edges and loops in jewelry wire. These can be used to create a larger range of products, from simple earrings to intricate necklaces. The flexibility of the tool makes it ideal for cutting and shaping wire, as well as bending it into curves that may make or break your design.

have a moving pivot point or fulcrum on their jaws. This allows the jaws to expand and contract, thus increasing and decreasing the size of their grip range. For example, one model of slip joint pliers has two different positions for its pivot point. If you are trying to fix two things at once, or if the two things have surfaces at odd angles, having multiple positions will help you accomplish your task.

The product is made of platinum steel and undergoes rigorous testing to ensure quality. The handles are reinforced, and the working surfaces receive a chrome plating that prevents damage from accidents. Moreover, the pliers have a special bulge that prevents fingers from being caught in between working surfaces during operation.

A non-slip joint that can lock on pipes and nuts. It requires low hand force, and it prevents slipping on the work piece. This is because of its jaw profile, which can fit screws and nuts, and its joint design, which decreases strain on the center bolt. Because of this strain decrease, there is no wear on the pivot point. A guard prevents operators from getting pinched.

🔍 Key Differences: European vs Japanese Circlip Pliers

|

Feature |

European Style |

Japanese Style |

|

Tip Construction |

Usually straight machined tips (or with a slight taper) |

Often forged or pressed tips, some with integrated hooks |

|

Tip Angle Options |

Available in straight, 45°, and 90° |

More often fixed 90° or specialized application angles |

|

Body Structure |

Thicker arms, bulkier construction |

Slimmer, compact, often more minimalist |

|

Material Preference |

Chrome Vanadium / Cr-Mo / tool steel |

High-carbon or alloy steel (precision-ground) |

|

Grip Style |

Ergonomic dipped grips or two-tone sleeves |

Straight, minimalist grips, often with knurled metal ends |

|

Spring Mechanism |

Internal or external spring-assisted (many models) |

May lack a spring, relies on user control |

|

Retaining Ring Tolerance |

Optimized for DIN or ISO standard rings |

Optimized for JIS (Japanese Industrial Standard) tolerances |

|

Typical Application Use |

Common in automotive, heavy machinery, and European tools |

Popular in electronics, fine mechanics, and small engines |

|

Brand Examples |

KNIPEX, WIHA, Felo, Gedore, NWS |

ENGINEER Inc., Vessel, Fujiya |

|

Pin Tip Type |

Detachable tips optional (in higher-end sets) |

Fixed-tip only, fewer modular options |

🔧 Summary

- European-style circlip pliers are usually more robust, built for heavy-duty applications, and cater to DIN standards, widely used in automotive and machinery.

- Japanese-style circlip pliers tend to be more precise and compact, built for fine mechanical work, electronics, or smaller internal mechanisms—especially common in motorcycles and home appliances.