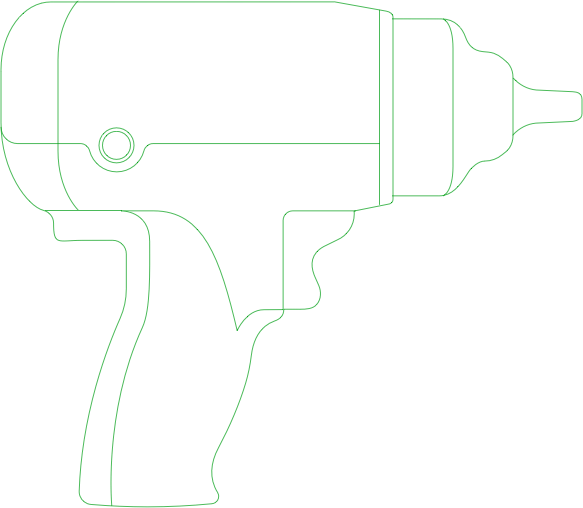

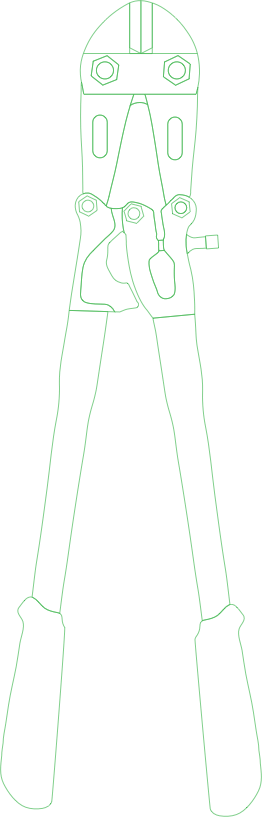

World-Class Tools

for Industrial and Professional

MORE

PRODUCTS

Strong Tools. Real Work

Empowering Professionals

Made for the World, Built to Last.

Connecting Industries, Delivering Results

Established

After World War Ⅱ, U.S army imported most of hand tools manufacturing skills & techniques into Taiwan for supplying militaries support in Vietnam, Japan or Korea.

Global Partnerships

Partners with global industrial market that support the empowerment of local distributions. Hans Tools works over decades to deliver quality to the world.

Nations

Hans Tools is delighted to close customers in worldwide. Sales force and business channel ensure that our services always reach your expectations.

Items

Through the company’s heritage of supplying top industry manufactures and international sales teams, The brand is known for its durability and long-lasting performance, as well as its competitive prices.

MISSION

Industrial Sense

Credibility

Stability

NEWS

Evolving Mobility: How Precision Engineering Transforms People’s Interaction with Tools

August 12, 2025

Introduction: Mobility today is more than getting from point A to B. It’s a fast-changing ...

AMKL 2025: HansTools Strengthens Presence in ASEAN Market

May 21, 2025

A New Chapter in Southeast Asia: HansTools Sponsorship Experience at Automechanika Kuala Lumpur 2025 AMKL ...

Forging New Connections: HansTools Joins 2025 Taiwan Trade Mission Across Europe and the UK

May 19, 2025

Taiwan Trade Mission 2025: HansTools Expands Presence Across Western Europe Following our momentum from Automechanika ...

Beyond the Basics: Innovative Uses of Wheel Service Tools

February 20, 2025

Introduction:Welcome to our latest exploration on hanstool.com where we dive into the world of wheel ...

The Significance of the Taiwan Trade Mission: Empowering HansTools and the Hand Tool Industry

August 20, 2024

Taiwan Trade Mission has been organized by Taitrade (Taiwan External Trade Development Council) for decades, ...

Automechanika Frankfurt and IAA Transportation Hannover

August 15, 2024

• Automechanika Frankfurt is one of the world’s largest trade fairs for automotive parts and ...

Discover HansTools: Quality Tools for Professionals in Philippines

November 8, 2023

Discover HansTools: Premium Tools for Professionals in PH Explore the durability and versatility of HansTools ...

2023 HansTools participates at NHS-(National Hardware Show) in Las Vegas USA

January 31, 2023

As a leading hardware and home improvement trade show, NHS is excited to announce its ...

CONTACT US