🔩 Overview: Impact Bit Sockets vs. Hand Bit Sockets

Bit sockets are essential tools for fastening jobs, but not all are built the same. Understanding the difference between impact bit sockets and hand bit sockets is crucial for selecting the right tool for the job.

Number and Types of Bit Sockets Available

- The market offers bit sockets in both SAE and metric sizes, covering a broad range of dimensions and drives including 1/4”, 3/8”, 1/2”, and 3/4” drive sizes.

- Types include hex bit sockets, star bit sockets, spline bit sockets, tamper-resistant bit sockets, Phillips, slotted, and Ribe bit sockets, among others.

- Bit sockets come in various lengths such as standard, mid, long, and extra-long to accommodate different working conditions and depths.

- Manufacturers like PROTO®, Performance Tool®, Sonic Tools, and HansTool offer extensive selections with features like corrosion resistance, heat treatment, and high torque endurance

Overview of Bit Sockets in the Market Bit sockets are widely available in various sizes, drives, and types to meet different industrial and automotive needs. They are typically made from durable materials such as S2 steel and chrome vanadium (Cr-V) steel, often manufactured in Taiwan for quality assurance.

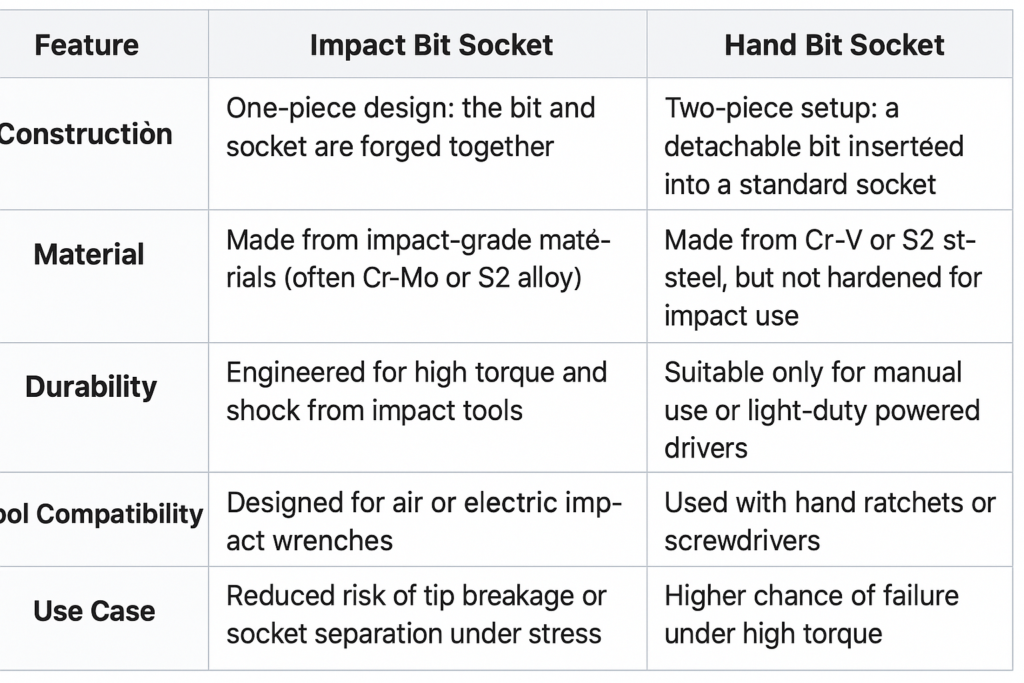

Feature Comparison

(Placeholder image—actual chart can be created using a graphic design tool)

Key Differences

Impact Bit Socket: One-piece design, built for high torque applications using impact wrenches.

Hand Bit Socket: Two-piece design, better suited for manual use with ratchets or screwdrivers.

Material: Impact-grade Cr-Mo/S2 alloy vs. standard Cr-V/S2 steel.

Safety: Impact bit sockets minimize tip breakage, while hand bit sockets may fail under high torque.

Use Cases: Automotive, industrial, heavy-duty vs. general-purpose and DIY.

🔧 Complete Guide to HansTools Bit Socket Series

🔧 HansTools Bit Socket Series Overview

🔧 Why Impact Bit Sockets Matter

Unlike hand bit sockets, impact bit sockets are built as a single, solid unit. This eliminates the weak point where the bit could detach from the socket during high-torque applications. That’s why they’re the preferred choice in heavy-duty automotive repair, construction, and factory maintenance.

Choosing the right socket saves time, improves safety, and extends tool life.

Feature | Impact Bit Socket | Hand Bit Socket |

Construction | One-piece design: the bit and socket are forged together | Two-piece setup: a detachable bit inserted into a standard socket |

Material | Made from impact-grade materials (often Cr-Mo or S2 alloy) | Made from Cr-V or S2 steel, but not hardened for impact use |

Durability | Engineered for high torque and shock from impact tools | Suitable only for manual use or light-duty powered drivers |

Tool Compatibility | Designed for air or electric impact wrenches | Used with hand ratchets or screwdrivers |

Use Case | Ideal for automotive, industrial, or heavy-duty applications | General-purpose, light-duty maintenance or DIY tasks |

Safety | Reduced risk of tip breakage or socket separation under stress | Higher chance of failure under high torque |